ME-317 MANUFACTURING PROCESSES-II

CREDIT HOURS

Theory = 3

Practical = 1

COURSE LEARNING OUTCOMES (CLOs)

| S. No. | CLOs | Taxonomy |

| 1 | Describe machining process and technical detail and discuss their applications according to particular manufacturing requirements | Coginitive Level 2* |

| 2 | Analyze manufacturing tasks, identify relevant machining processes and perform pertinent calculations | Coginitive Level 4* |

| 3 | Classify and characterize various measurement and tolerance techniques | Coginitive Level 3* |

| 4 | Observe performance of various machining operations and perceive the importance of sustainable use of resources and their environmental impacts | Psychomotor Level 1,3,4* |

| 5 | Contribute in Lab work at individual and group level | Affective Level 2* |

COURSE CONTENT

- Machine Tools

- Machine tools using single point tools, description, functions, operations performed on lathe, shaper, planer, and boring machines.

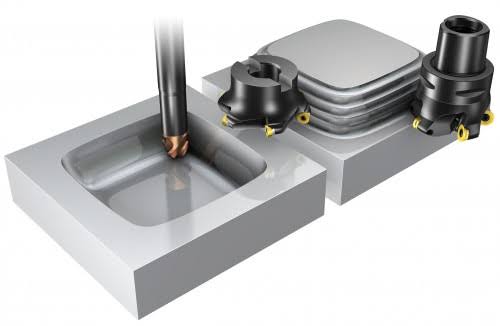

- Machine tools using multiple cutting edge tools, description, functions, and operations performed on drilling, milling, gear cutting, broaching machines, and thread manufacturing.

- Machine tools using abrasive wheels, description and functions of various types of grinding machines, wheel dressing and wheel balancing, honing, lapping, and super finishing operations.

- Work Holding Devices: Basic concept and design of different work holding devices like chuck, vices, jigs and fixtures for lathe, milling, drilling etc.

- Machining Parameters: Determination of machining time and material removal rate for various machining operations, cutting tools for manufacturing, cutting tool material characteristics, cutting tool materials, tool steels, HSS, sintered carbides, ceramics, tin-coated HSS, diamonds and cubic boron nitrides, tool geometry, tool life, tool wear and machinability, Taylor’s tool life model, sharpening and reconditioning of cutting tools, Basic concept and design of jigs and fixtures.

- Non-Traditional Machining Processes: EDM, ECM, and ultrasonic machining.

- Metrology:

- Light waves as standard of length, design and operation of linear measuring instruments, slip and block gauges, length bars, limit gauges, sine bar, reference temperature, limits and fits, hole-basis, shaft basis comparators, mechanical, electrical, pneumatic and optical.

- Errors in measurement, sensitivity, accuracy and variation, economics of measurement, measurement of squareness, flatness, straightness, roundness, gear and screw threads, advanced measuring and inspection non-contact measurement, machine tool metrology, alignment tests, level of installation, spindle straightness, flatness and squareness.

- Surface Texture and Measurement: Roughness and measurement of roughness lay, waviness and flaws, CLA and RMS values, predication and average values of roughness for various manufacturing processes like turning, drilling, milling and grinding.

- Standardization: Introduction, Interchangeability, assembly, principles, preparation of standards, application of standards in design and manufacturing. Standards organizations.

RECOMMENDED BOOKS

(01) DeGarmo's Materials and Processes in Manufacturing by J. T. Black

(02) Fundamentals of Modern Manufacturing: Materials, Processes, and Systems by Mikell P. Groover

(03) Manufacturing Engineering and Technology by Serope Kalpakjian & Stephen R. Schmid

*For details of Taxonomy Levels CLICK HERE!