ME-220 MANUFACTURING PROCESSES-I

CREDIT HOURS

Theory = 3

Practical = 1

COURSE LEARNING OUTCOMES (CLOs)

| S. No. | CLOs | Taxonomy |

| 1 | Discuss in detail the processes of manufacturing of metallic and plastic parts | Coginitive Level 2* |

| 2 | Compare between different types of metal forming processes and differentiate between their output product characteristics | Coginitive Level 4* |

| 3 | Describe different types of joining processes and introduce the concept of sustainable manufacturing | Coginitive Level 2* |

| 4 | Contribute positively at the individual as well as team level | Affective Level 2* |

COURSE CONTENT

- Introduction to Manufacturing: Types of manufacturing industries, materials used in manufacturing and properties of materials, different processing operation.

- Sand Casting:

- Introduction: Sand casting, molding, heating and pouring, solidification and cooling. Pattern: making, material, types, construction, pattern allowances.

- Core: making, types, sand conditioning, testing of sand, molding process, tools and equipment, molding machines, different types of casting, cleaning and finishing of castings, inspection of castings.

- Permanent Mold Casting (PMC): Introduction, types of PMC, gravity die casting and its types. Pressure die casting, Centrifugal casting and their types. Furnaces used in PMC.

- Metal Forming:

Fundamentals, types, hot, warm and cold working.

Bulk Deformation Processes:- Rolling; rolled products, rolling types: flat, shape, thread, gear, ring rolling, and rolling mill configurations.

- Forging; open die, impression die, press, upset, roll, net shape, isothermal forging and swaging.

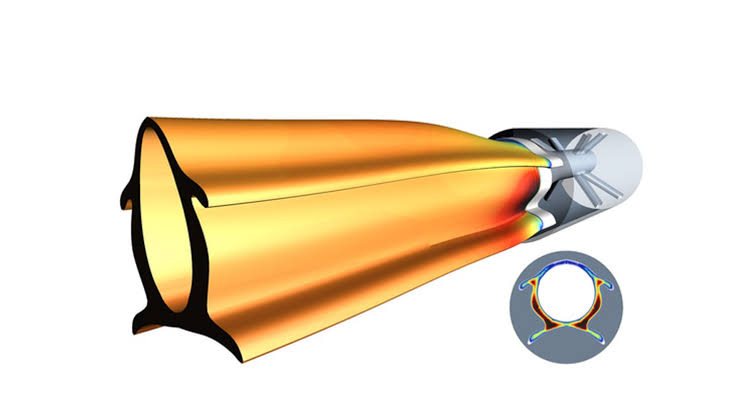

- Extrusion; solid & hollow shapes, direct & indirect, hot & cold, continuous & discrete, impact extrusion, hydrostatic.

- Drawing; bar, wire, tube drawing and its types tike tube sinking, fixed mandrel, floating plug.

Other metal forming processes; roll extrusion, riveting, staking, peening, coining, hubbing, burnishing.

- Sheet metal forming processes: Shearing operations: slitting, blanking, piercing, cutoff, parting, dinking, slotting, perforating, notching, semi-notching, lancing, nibbling, trimming, shaving, fine blanking. Bending operations: V bending, edge bending, flanging, curling, hemming, seaming. Drawing operations like deep and shallow drawing, embossing.

- Welding Processes: Classification, Fusion welding and its types such as oxyfuel gas welding and oxygen torch cutting, arc welding (shielded metal, flux cored, gas metal, submerged, gas tungsten, plasma, stud welding, Arc cutting), resistance welding (spot, seam and projection. Heating, pressure, current control and power supply for resistance welding).

Solid state welding and its types including diffusion welding, friction welding and ultrasonic welding.- Other welding processes: Forge, Roll, Friction, Explosion, Thermic, Electron beam, Laser welding and cutting, Brazing and Soldering.

- Fabrication of Plastics: Casting, Blow molding and its types, Compression molding, Transfer molding, Cold molding, Injection molding: injection molding machine, mold design and construction, types of mold, cooling and ejection of mold, Reaction injection molding, Welding of plastics.

RECOMMENDED BOOKS

(01) DeGarmo's Materials and Processes in Manufacturing by J. T. Black

(02) Fundamentals of Modern Manufacturing: Materials, Processes, and Systems by Mikell P. Groover

(03) Manufacturing Engineering and Technology by Serope Kalpakjian & Stephen R. Schmid

*For details of Taxonomy Levels CLICK HERE!