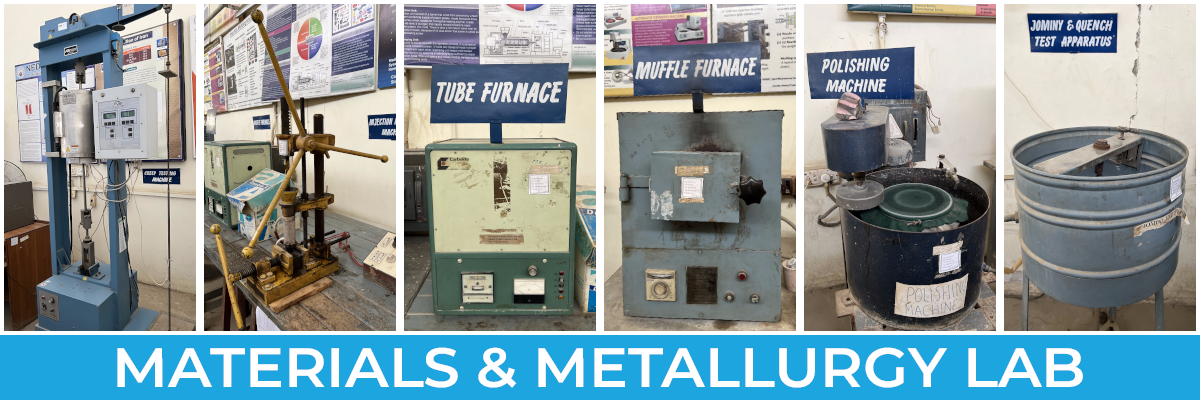

ME-209 MATERIALS & METALLURGY

CREDIT HOURS

Theory = 3

Practical = 1

COURSE LEARNING OUTCOMES (CLOs)

| S. No. | CLOs | Taxonomy |

| 1 | Discuss material crystallography and materials mechanical properties | Coginitive Level 3* |

| 2 | Analyze the phase diagram | Coginitive Level 4* |

| 3 | Discuss the environmental degradation of engineering materials | Coginitive Level 2* |

| 4 | Observe the microstructural changes in the heat treated metal specimen | Psychomotor Level 1* |

COURSE CONTENT

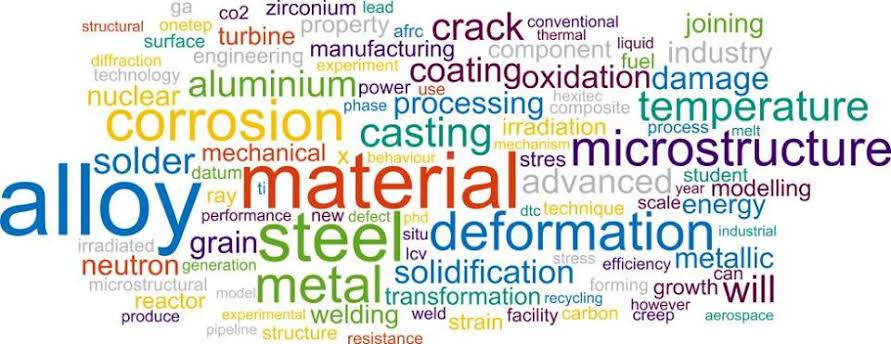

- Introduction: Importance of Material Science and Engineering, classification of materials, material property charts

- Crystallography: Types of crystal structures, atomic packing factor, Miller indices of crystallographic planes and directions

- Imperfections in solids: Classification of defects, types of point defects and their effects on material properties, dislocations, kinetics of dislocations, dislocation interactions, significance of dislocations on material permanent deformation

- Mechanical properties of materials: Deformation behavior of materials under tensile and compressive loads, Hardness testing, Testing of materials under impact loading, fundamentals of fracture mechanics, importance of fracture mechanics, material characterization of fracture surfaces, stress distribution around a crack, fatigue testing, S-N curves, creep deformation behavior & ASTM standards for all mechanical tests

- Diffusion in materials: Diffusion theory, equilibrium and non-equilibrium diffusion mechanisms, effect of diffusion on material properties

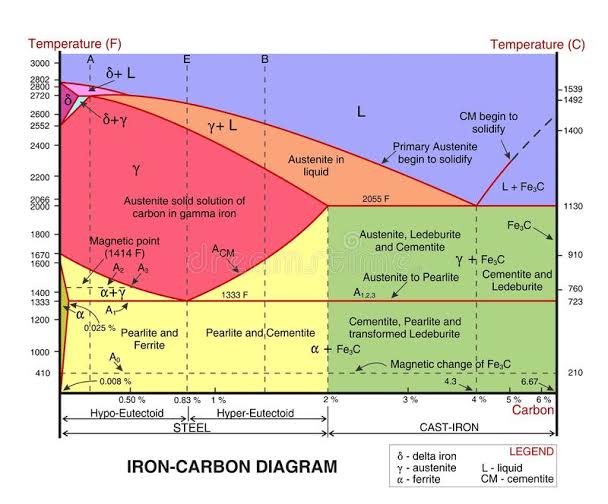

- Heat treatment and phase transformation in materials: Types of heat treatment processes, effects of heat treatment on material structure and properties, concepts of phases in solids, solubility limit in solid solutions, strengthening mechanisms (solid solution and precipitate strengthening), binary phase diagrams, iron-iron carbide phase diagram, diffusional and non-diffusional phase transformation, kinetics of phase transformation

- Polymers: Structure of Polymers, Thermoplastics and Thermosetting Polymers, Copolymers, Polymer Crystals, Defects in Polymers Characteristic

- Applications and Processing of Polymers: Mechanical Behavior, Viscoelasticity, Fracture, Strengthening Mechanism, Polymer Types, Polymer Processing

- Ceramics: Ceramic Structure Imperfections in ceramics, Mechanical Properties

- Applications and Processing of Ceramics: Types and Applications, Fabrication and Processing

- Composites: Introduction, Particle Reinforced Composites, Fiber Reinforced Composites, Processing of Composites, Sandwich Panels

- Material degradation, corrosion, Stress corrosion cracking, corrosion prevention

- Nanomaterials: Classifications of nanomaterials, nanomaterial properties, synthesis and characterization of nanomaterials, significance and application of nanomaterials

- Advanced high strength steels: Classification of AHSS, material and mechanical characterization of AHSS, properties and applications of AHSS

RECOMMENDED BOOKS

(01) Material Sciences & Engineering – An Introduction by William D. Callister

(02) Principles of Material Sciences & Engineering by William F. Smith

*For details of Taxonomy Levels CLICK HERE!