MC-504 MECHANICS OF MATERIALS & PROCESSES

Credit Hours = 3

COURSE CONTENT

- Deformation; strain; elastic stress-strain behaviour of materials; Introduction to stress-strain diagram, working stresses, unit design, Poisson’s ratio; Determination of forces in frames; Simple bending theory; general case of bending; Shear force and bending moment diagrams; Relationship between loading; shear force and bending moment.

- Direct shear, hydrostatics and complementary shear stresses; bar and column; thin ring, elementary thermal stress and strain. Strain energy in tension and compression. Analysis of bi-axial stresses, principal planes, principal stress-strain, stresses in thin walled pressure vessels.

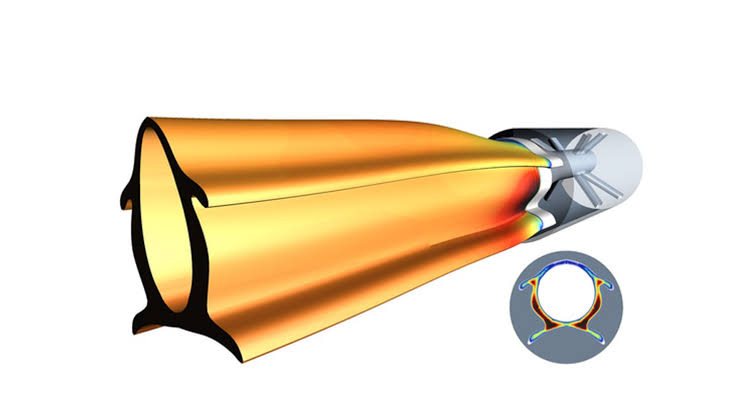

- Torsion of circular shafts, coiled helical spring, strain energy in shear and torsion of thin walled tubes, General case of plane stresses, principal stress in shear stresses due to combined bending and torsion plane strain. Theories of Yielding, Stress Concentration.

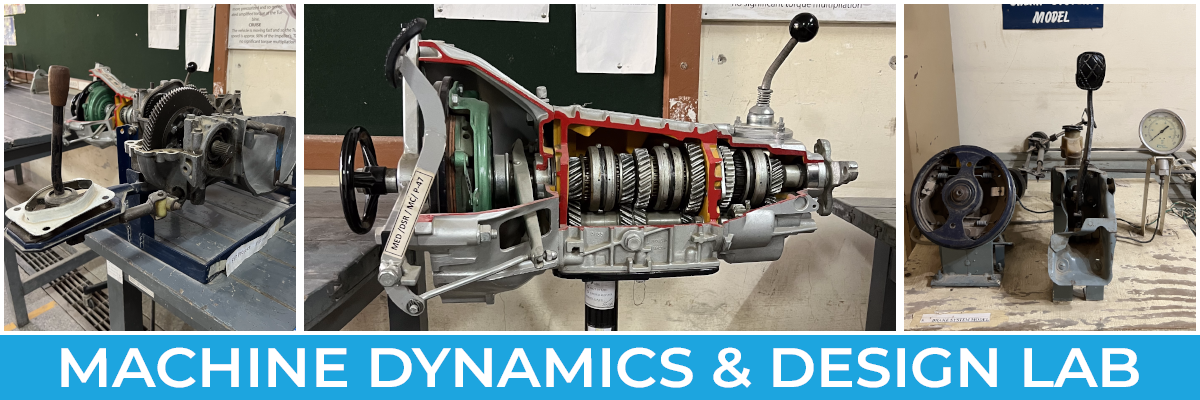

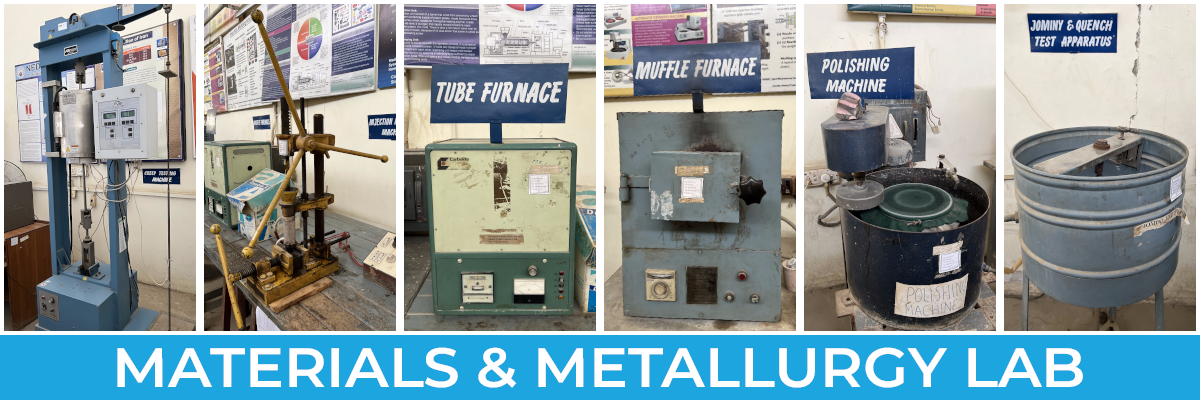

- Machining Process and Machine Tools: Machine tools using single edge cutting tools, and multiple edge cutting tools, Description, and operations; performed on lathe, shaper, Planner, drilling, milling, gear cutting, and broaching machines. Work holding devices.

- Machine tools using abrasive wheels; description and functions of various types of grinding machines; wheel dressing, and wheel balancing; Honing, lapping, and super finishing operations; thread manufacturing.

- Cutting tools for manufacturing: Cutting tool material characteristics; Cutting tool materials; Tool Geometry; Non-traditional machining processes such as EDM, ECM, & ultrasonic machining.

- Welding Processes: Classification of welding processes; oxyacetylene welding. Oxygen torch cutting, and flame straightening; Arc welding; Shielded arc welding, Gas tungsten arc welding, Gas metal arc welding, Flux-cored arc welding, submerged arc welding, spot welding, Seam welding, Projection welding. Brazing and Soldering.

- Fabrication of Plastics: Casting; Blow Moulding; Compression Moulding; Transfer Moulding; Cold Moulding; Injection Moulding; Reaction Injection Moulding; Vacuum Forming; Welding of plastics.

RECOMMENDED BOOKS

Coming Soon