ME-531 COMPUTER AIDED MANUFACTURING (CAM)

Credit Hours = 3

COURSE CONTENT

- CNC Machine Tools: A historical perspective, Principal of numerical control, Typical CNC machine tools, Tooling for CNC machines, Principal elements of a CNC machine, Axis and motion of CNC machines, Economics and justification.

- NC Part Programming: Punched tape in NC, Tape coding and format, Manual part programming, Computer assisted part programming, The APT language, NC programming with interactive graphics, Manual data input, APT word definitions.

- CNC Milling Programming: Basic programming commands, Compensation and offset, Fixed cycles, Macro and subroutine programming, Tooling system for CNC milling.

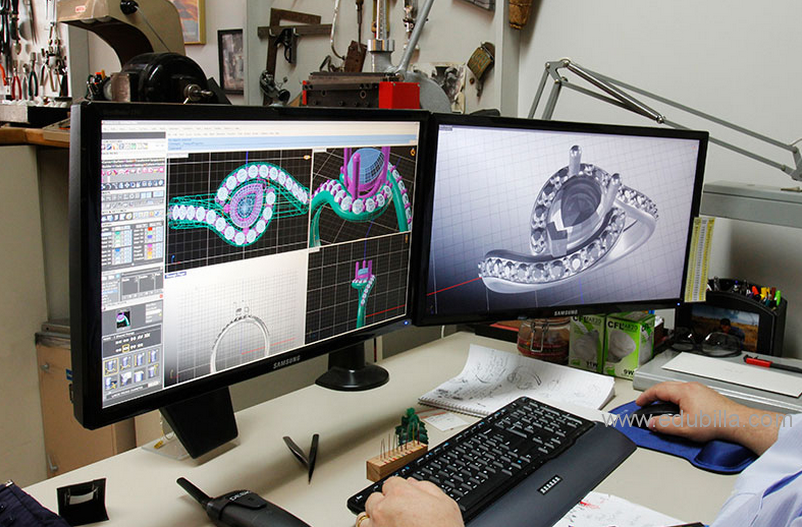

- Fundamentals of Sculptured Surface Machining: Introduction to sculptured surface machining, Mathematical background, Sculptured surface machining processes, Process planning for sculptured surface machining, Fundamentals of tool-path generation and validation, Project.

- Tool-Path Generation Methods for 3-Axis Sculptured Surface Machining: Introduction to 3-axis CNC tool paths, Types of 3-axis CNC tool paths, Iso-parametric tool Paths, Parallel tool Paths, Iso-cusps tool Paths, Steepest-ascending tool Paths, Project.

- Automated Manufacturing Systems: Schemes for concurrent engineering, Axiomatic design, DFM guidelines, Design for assembly, The Taguchi method for robust design, Manufacturing process design rules, Computer-Aided DFM, Group technology, Failure-Mode and Effects Analysis.

- Programming in MATLAB: Basic programming concepts, Import CAD data from CAD/CAM software, Tool path generation in MATLAB, Project.

RECOMMENDED BOOKS

Coming Soon