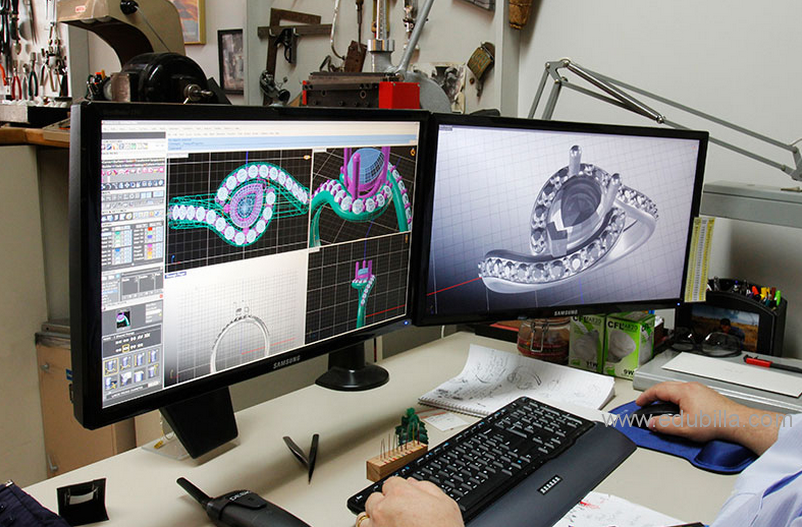

ME-522 COMPUTER AIDED MANUFACTURING (CAM)

Credit Hours = 3

COURSE CONTENT

- Conventional Numerical control: Introduction, basic components of an NC system, the NC procedure, NC coordinate systems, NC motion control systems, applications of numerical control, economics and justification.

- NC Part Programming: Punched tape in NC, tape coding and format, manual part programming, computer assisted part programming, the APT language, NC programming with interactive graphics, voice NC programming, manual data input, APT word definitions.

- Computer Controls in NC: Problems with conventional NC, NC controller technology, computer numerical control, direct numerical control, adaptive control machining systems, trends and new developments in NC.

- Group Technology and FMS: The role of group technology in CAD / CAM integration; Methods for developing part families; Classification and Coding: Hierarchical code, Attribute code, Hybrid code, Selecting a coding system, Development your own coding system; Coding systems: OPITZ coding system, MICLASS coding systems; Facility design using group technology; Cell design; Economic modeling in a group technology environment: Production planning cost model, Group tooling economic analysis; Economics of group technology: Benefits in Design, Benefits in manufacturing, Benefits to management, Group technology advantages / disadvantages summarized. Introduction to FMS, FMS workstations, materials handling and storage system, computer control system, planning the FMS, analysis methods for FMS, application and benefits.

- Process Planning: The role of process planning in CAD / CAM integration, Approaches to process planning: Manual approach, Variant approach, Generative approach; Process planning systems: CAM-I automated process planning (CAPP), DCLASS, Computer Managed process planning (CMPP), Machinability data system.

RECOMMENDED BOOKS

Coming Soon