ME-514 ADVANCED METALLURGY

Credit Hours = 3

COURSE CONTENT

- Physical Processing of Metal: Simulation of the role of continuous casting fluxes, extrusion of Cu alloys, production of Al Mg alloys from the powder phase. Deformation of austenitic stainless steel, extrusion of Al-Mg-Si compacts. Extrusion of Al-Mg alloys, rolling of Al-Mg alloys, deformation of flow and pressure requirements for the extrusion of Al-Cu-Mn Mg shapes, the preparation of high modulus low density engineering materials from rapidly solidified powders, factors controlling the production of tubular shapes from rapidly solidified materials, engineering materials prepared from rapidly solidified powders using the conform process.

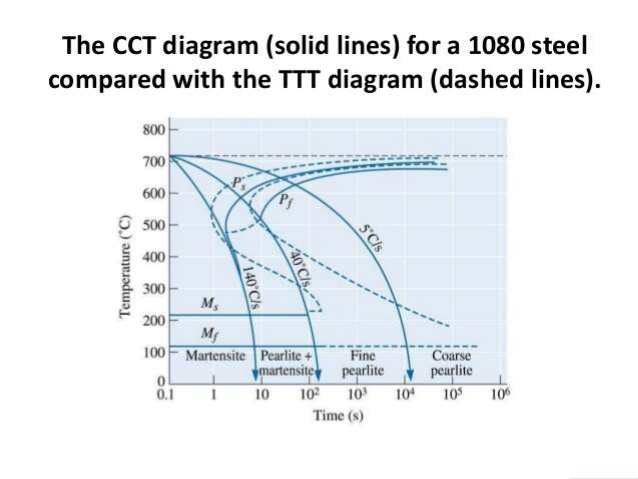

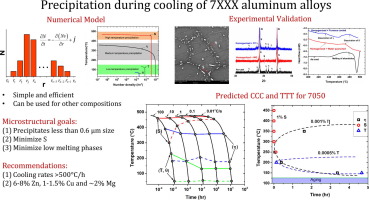

- Phase Transformations: Precipitate dissolution in aluminum alloys, Grain boundary precipitation and toughness in Al-Li-x alloys, Constitutional effects of platinum groups metals and refectory metals in nickel based superalloys, Precipitation effects in nickel based alloys containing Mo and W, high temperature titanium alloys, Phase equilibria in recycled martensite formation in titanium alloys.

- Structural Aspects of Metals: Microstructure and microchemistry development in alloys, effect of microstructure on the wear, erosion and mechanical properties of Silceram glass-ceramics, high temperature plasticity and dynamics of recrystallisation in polycrystalline metals, minerals and analogues, The effect of second-phase particles on high temperature deformation, creep fatigue of nimonic alloys, automated determination of diffraction patterns and textures in the transmission electron microscope, the effects of process variables on the microstructure and toughness of Al-Li based alloys, microstructure and mechanical properties of triballoys.

- Corrosion: Protective coatings for steels in sulphide environments, properties of metallic coatings, oxidation and hot corrosion in metals of industrial importance, laser and other methods of surface treatment for marine corrosion protection.

RECOMMENDED BOOKS

Coming Soon